XP DUR 600 Hardfacing Wire

Seamless HF Cored Wire

XP DUR 600 Hardfacing Wire

Seamless HF Cored Wire

Product Code (SKU):

DUR600-C-Wire-XP

Categories: Cored Wire, Hardfacing Cored Wire, Welding Consumables, Welding Wire, XP

Product Tags: DUR600, Hardfacing, Metal Cored, Wire, XP, XP Welding Wire

£0.00

For More Info Please Call Sales:

UK & Éire Sales:

Rest of the World ( Export ) Sales:

Please Call Sales To Place An Order:

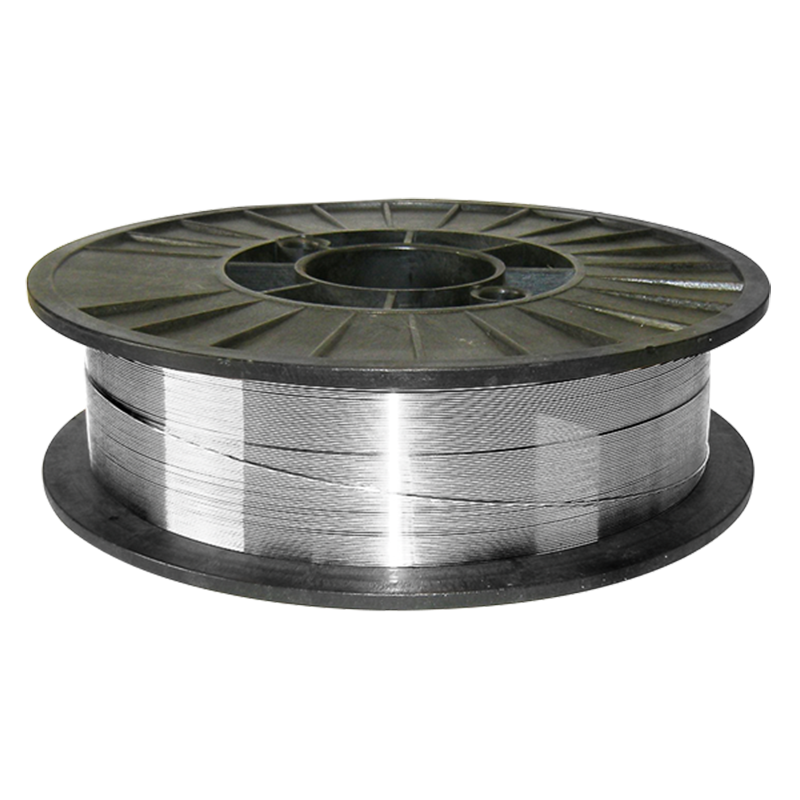

Cored (DUR600) welding wire for hardfacing applications.

- Seamless metal cored wire designed for wear-resistant hardfacing applications.

- Provides excellent resistance to abrasion, impact and edge retention.

- Typically, 20% higher deposition rates than solid wires.

- No slag to remove post welding due to metal core.

- Typical diffusible hydrogen content is < 3.0 ml 100 g. Guaranteed for the total processing time < 4.0 ml 100 g.

- This alloy deposits a martensitic structured weld-metal.

- Commonly used in hardfacing applications within the earthmoving, quarrying and agricultural sectors.

- Vacuum packed to control moisture levels

Approvals:

- EN ISO: 14700

- T Fe2

Welding Positions:

| Weight | 15 kg |

|---|---|

| Dimensions | 300 mm |

| Material | Hard Facing |

| Shielding Gas | Mixed Gas |

| Hardness | Third Layer 57 – 62 HRC |

| Spool | BS300 |

| Current Type | DC+ |

| Grade | T Fe2 |

| Set Size | Single Box |

| Conforms To | EN ISO 14700 |

Be the first to review “XP DUR 600 Hardfacing Wire” Cancel reply

Share Product Via:

Facebook

Threads

WhatsApp

X

LinkedIn

Email

Print

Featured Products:

Related products

-

XP ER 316LSi Wire

Stainless Steel MIG Wire

-

XP ER 4043 (AlSi5) Wire

Aluminium, 5% Silicon

You may also like…

-

XP ER 308LSi Wire

Stainless Steel MIG Wire

-

XP 110 (ER110S-G) Wire

High Strength MIG Wire

-

XP ER 347Si Wire

Stainless Steel MIG Wire

-

XP CrMo2Si (ER 90S-G) Wire

Creep Resistant MIG Wire

Reviews

There are no reviews yet.